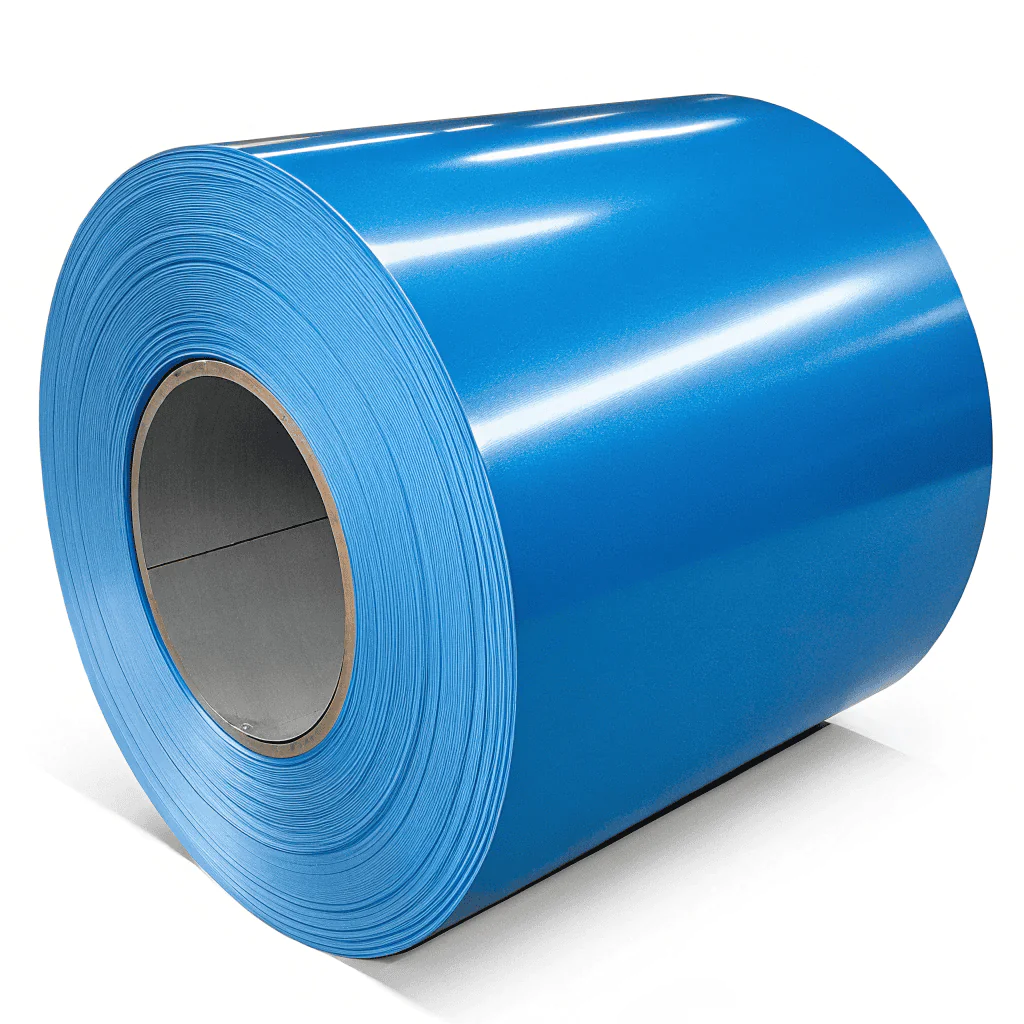

PPGI

Technical Specifications

Material:

AL-ZN ,Q235

Zinc Coating:

30g-900g/m2

Standard:

ASTM, JIS, GB, AISI, DIN, BS

Certificated:

ISO, RoHS, IBR

HS Code:

3316965037

Product Description

PPGI DESCRIPTION

| Category | Parameter | Specification | Unit/Standard | Remarks |

|---|---|---|---|---|

| BASE MATERIAL | Steel Grade | DX51D, DX52D, DX53D, DX54D | EN 10346 | - |

| Thickness Range | 0.12 - 2.0 | mm | Tolerance: ±0.02mm | |

| Width Range | 600 - 1,500 | mm | Tolerance: ±2mm | |

| Coil Inner Diameter | 508 / 610 | mm | - | |

| Coil Weight | 3 - 8 | MT | Customizable | |

| Camber | ≤ 2 | mm/m | - | |

| Flatness | ≤ 3 | mm/m | - | |

| ZINC COATING | Coating Weight | 60 - 275 | g/m² | ISO 3575 |

| Coating Type | Z60, Z80, Z100, Z120, Z180, Z275 | - | Both sides | |

| PAINT COATING - PE | Top Coat Thickness | 15-25 | μm | ISO 2808 |

| Weather Resistance | 8-10 | years | Indoor use | |

| Salt Spray Test | 500 | hours | ISO 9227 | |

| PAINT COATING - SMP | Top Coat Thickness | 20-25 | μm | ISO 2808 |

| Weather Resistance | 10-15 | years | General purpose | |

| Salt Spray Test | 750 | hours | ISO 9227 | |

| PAINT COATING - HDP | Top Coat Thickness | 25 | μm | ISO 2808 |

| Weather Resistance | 15-18 | years | Outdoor structures | |

| Salt Spray Test | 750 | hours | ISO 9227 | |

| PAINT COATING - PVDF | Top Coat Thickness | 25-35 | μm | ISO 2808 |

| Weather Resistance | 20-25 | years | Premium applications | |

| Salt Spray Test | 1,000 | hours | ISO 9227 | |

| COATING COMMON | Primer Thickness | 5 - 10 | μm | All types |

| Back Coat Thickness | 5 - 25 | μm | All types | |

| Total Coating Thickness | 20 - 60 | μm | Depends on type | |

| MECHANICAL PROPERTIES | Pencil Hardness | ≥ 2H | ISO 15184 | - |

| Adhesion (Cross-cut) | Grade 0 | ISO 2409 | Best grade | |

| Reverse Impact | ≥ 9 | J | ASTM D2794 | |

| T-Bend Test | ≤ 3T | ISO 17132 | - | |

| MEK Resistance | ≥ 50 | double rubs | ASTM D4752 | |

| Cupping Test | ≥ 6 | mm | ISO 1520 | |

| WEATHER PERFORMANCE | UV Resistance | ΔE ≤ 2 | ISO 11507 | 1000 hrs test |

| Gloss Retention | ≥ 60% | ISO 2813 | 1000 hrs test | |

| Color Fastness | Grade 4-5 | ISO 105-A02 | - | |

| Color Difference | ΔE ≤ 1.5 | - | Production control | |

| THERMAL PROPERTIES | Service Temperature | -40 to +80 | °C | Continuous |

| Heat Resistance | 120 | °C | Short term | |

| COLOR OPTIONS | RAL Classic | RAL 1000-9999 | - | Standard colors |

| Pantone | Custom matching | - | On request | |

| Special Effects | Metallic, Pearl, Matte | - | Available | |

| Wood/Stone Patterns | Digital printing | - | Premium option | |

| Gloss Level | 10-90 | % | Adjustable | |

| PACKAGING | Type | Eye to sky | - | Steel strapping |

| Moisture Protection | VCI paper + plastic film | - | Standard | |

| Edge Protection | Steel/plastic protectors | - | All coils | |

| Labeling | Full specs included | - | Batch traceable | |

| CERTIFICATIONS | Quality System | ISO 9001:2015 | - | Certified |

| Environmental | ISO 14001:2015 | - | Certified | |

| Product Standards | CE Marking | EN 14782, EN 14783 | European standard | |

| ASTM Compliance | A653, A792, A755 | - | US standard | |

| Environmental Compliance | RoHS | - | Lead-free |

Notes:

- All specifications can be customized according to specific project requirements

- Minimum order quantities may apply for custom specifications

- Contact technical department for detailed consultation