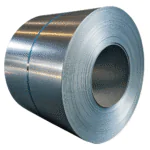

Galvanlume Steel Coil

Technical Specifications

Material:

SGCC/CGCC/Tdc51dzm/Tdc52dts350gd/Ts550gd/Dx51d+Z Q

Standard:

ASTM, JIS, GB, AISI, DIN, BS

Zinc Coating:

Z20-Z275, AZ15-AZ150

Thickness:

0.12mm~1.3mm

HS Code:

72107010

Product Description

Galvalume Steel Coil

Galvalume steel coils, also known as Aluzinc steel coils, are a type of coated steel product that combines the corrosion resistance of aluminum with the galvanic protection of zinc. The term “Galvalume” is a registered trademark owned by BIEC International Inc., and it refers specifically to their product.

Technical Specifications

| Parameter | Specification |

|---|---|

| Thickness Range | 0.12mm - 4.0mm |

| Width | 600mm - 1500mm (customizable) |

| Coating Weight | AZ30 - AZ275 (90-275 g/m²) |

| Coil ID | 508mm / 610mm |

| Coil Weight | 3-8 MT (customizable) |

| Surface Treatment | Regular spangle, Minimized spangle, Zero spangle |

| Standards | ASTM A792, JIS G3321, EN 10346, AS 1397 |

| Available Grades | CQ, DQ, DDQ, S220GD-S550GD |

Key Features

| Feature | Description |

|---|---|

| Corrosion Resistance | 1000+ hours salt spray test; 4x longer lifespan than galvanized steel |

| Heat Reflectivity | Reflects 75% heat radiation; reduces cooling costs by up to 20% |

| Formability | Excellent bending and forming properties; suitable for deep drawing |

| Cost-Effectiveness | Lower maintenance requirements; reduced life-cycle costs |

| Durability | Self-healing properties protect cut edges and scratches |

Applications

| Industry | Applications |

|---|---|

| Construction | Metal roofing, wall cladding, structural framing, garage doors |

| Industrial | HVAC ductwork, electrical enclosures, storage tanks |

| Automotive | Heat shields, exhaust systems, underbody components |

| Agricultural | Grain bins, equipment housing, barn roofing |

| Infrastructure | Highway barriers, culverts, sound barriers, utility poles |

Quality Assurance

| Quality Aspect | Details |

|---|---|

| Certifications | ISO 9001:2015, ISO 14001:2015, CE Marking |

| Third-party Inspection | SGS, BV, TÜV available upon request |

| Testing Standards | Coating adhesion test, mechanical properties testing, chemical analysis |

| Quality Control | 100% inline inspection, complete mill test certificates provided |

| Packaging | Waterproof paper wrapping, steel strapping, seaworthy packing |