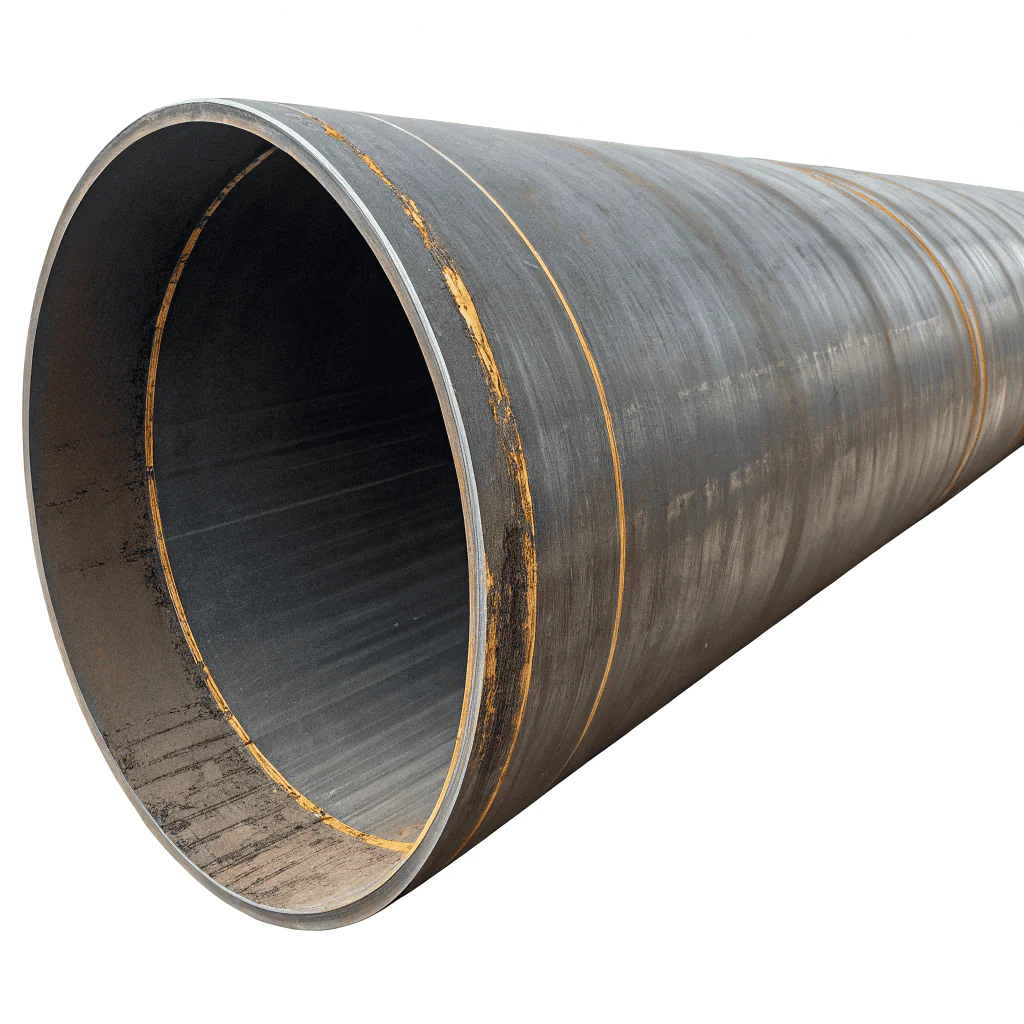

ERW Steel Pipe

Technical Specifications

Product Description

Product Introduction

Our welded steel pipes are manufactured using advanced high-frequency induction welding technology, providing an economical and reliable solution for various industrial applications. These pipes offer excellent versatility with a wide range of sizes and wall thicknesses to meet diverse project requirements.

With comprehensive quality control processes and adherence to international standards, our welded steel pipes deliver consistent performance and reliability for water transportation, gas distribution, and structural applications at competitive prices.

Technical Specifications

| Diameter Range | 1/2 inch to 24 inches (12.7 mm to 609.6 mm) |

| Wall Thickness | 0.5 mm to 12.7 mm |

| Standards Compliance | ASTM A53 API 5L EN 10219 |

| Material Grade | ASTM A53 Grade B API 5L Grade B |

| Welding Method | High-frequency induction welding (HFI) |

| Surface Finish | Polished and cleaned to international standards |

Manufacturing Process

1. Material Selection

High-quality carbon steel coils are carefully selected and inspected to ensure chemical composition and mechanical properties meet specified standards.

2. Precision Forming

Selected steel coils are formed into cylindrical shape using precision roller sets, ensuring consistent roundness and dimensional accuracy throughout the process.

3. High-Frequency Welding

The pipe edges are joined using high-frequency induction welding technology, creating a strong, reliable weld seam with minimal heat-affected zone.

4. Heat Treatment

Normalizing heat treatment is performed to enhance mechanical properties, relieve internal stresses, and improve overall pipe performance.

5. Finishing & Quality Control

Pipes undergo polishing, cleaning, and comprehensive inspection including dimensional checks, weld quality testing, and surface finish verification to meet international standards.

Primary Applications

Water Transportation Systems

Extensively used in municipal water supply networks, irrigation systems, and industrial water distribution where reliable flow and corrosion resistance are essential for long-term performance.

Gas Distribution Networks

Ideal for natural gas distribution systems, propane lines, and other gas transportation applications requiring consistent pressure handling and leak-tight joints.

Structural & Mechanical Applications

Widely employed in construction frameworks, mechanical supports, automotive components, and general engineering applications where strength and dimensional stability are important.

Low to Medium-Pressure Systems

Perfect for plumbing systems, HVAC applications, compressed air lines, and other medium-pressure fluid handling systems in commercial and industrial facilities.

Competitive Advantages

Cost-Effective Manufacturing

Advanced welding technology enables lower production costs compared to seamless pipes while maintaining high quality standards. This cost efficiency makes welded pipes an economical choice for large-scale projects without compromising performance requirements.

Exceptional Versatility

Available in an extensive range of diameters and wall thicknesses, providing flexibility to meet diverse application requirements. Custom sizing options ensure optimal fit for specific project needs across various industries.

Superior Surface Quality

High-frequency induction welding creates smooth, uniform weld seams that are polished and cleaned to achieve excellent interior surface finish. This ensures optimal flow characteristics and reduces pressure drop in fluid systems.

Reliable Performance

Consistent manufacturing processes and rigorous quality control ensure reliable performance in demanding applications. Heat treatment optimization enhances mechanical properties and dimensional stability for long-term service life.