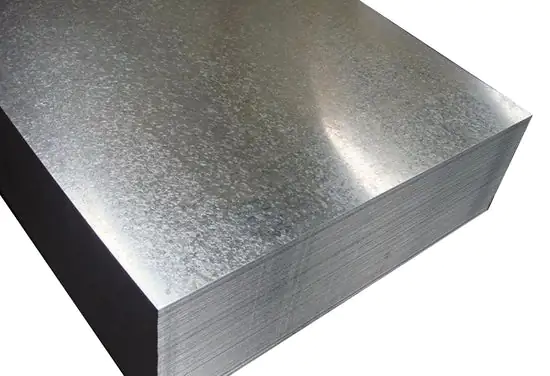

Galvanized Sheet

Technical Specifications

Product Description

GALVANIZED STEEL SHEET

Product Introduction

Galvanized steel sheets are premium quality steel products coated with a protective zinc layer through hot-dip galvanizing or electro-galvanizing processes. This coating provides exceptional corrosion resistance, extended service life, and superior surface finish, making them ideal for various industrial and commercial applications.

Features & Benefits

Superior Corrosion Resistance

Zinc coating provides long-lasting protection against rust and oxidation

Excellent Durability

Extended product lifespan reduces replacement costs

Versatile Applications

Suitable for construction, automotive, appliances, and manufacturing industries

Cost-Effective

Lower maintenance requirements and longer service life ensure optimal ROI

Formability

Easy to cut, bend, and fabricate according to specific requirements

Aesthetic Appeal

Smooth, uniform surface finish with bright metallic appearance

Product Specifications

| Parameter | Specification Range | Common Sizes |

|---|---|---|

| Thickness | 0.12mm - 6.0mm | 0.35mm, 0.45mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm |

| Width | 600mm - 1500mm | 914mm, 1000mm, 1200mm, 1219mm, 1250mm |

| Length | 1000mm - 6000mm | 2000mm, 2438mm, 2500mm, 3000mm, or coil |

| Coil Weight | 3MT - 8MT | 5MT (standard) |

| Coil I.D. | 508mm / 610mm | 508mm (standard) |

Zinc Coating Specifications

| Coating Class | Coating Weight (g/m²) | Coating Thickness (μm) | Application |

|---|---|---|---|

| Z60 | 60 | 8.5 | Light indoor use |

| Z80 | 80 | 11 | Indoor applications |

| Z100 | 100 | 14 | General purpose |

| Z120 | 120 | 17 | Moderate corrosion |

| Z180 | 180 | 25 | Outdoor use |

| Z275 | 275 | 39 | Heavy duty |

| Z350 | 350 | 49 | Severe environment |

| Z450 | 450 | 63 | Marine environment |

Steel Grade Options

| Grade Category | EN 10346 | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| Commercial Quality | DX51D+Z | - | 270-500 |

| DX52D+Z | 140-300 | 270-420 | |

| DX53D+Z | 140-260 | 270-380 | |

| Structural Quality | S220GD+Z | ≥220 | 300-420 |

| S250GD+Z | ≥250 | 330-430 | |

| S280GD+Z | ≥280 | 360-480 | |

| S320GD+Z | ≥320 | 390-510 | |

| S350GD+Z | ≥350 | 420-550 |

Surface Finish Options

| Surface Type | Code | Description | Roughness (Ra) |

|---|---|---|---|

| Regular Spangle | N | Normal zinc crystals visible | 1.0-1.9 μm |

| Minimized Spangle | M | Small zinc crystals | 0.6-1.0 μm |

| Zero Spangle | Z | Uniform matt finish | 0.6-1.0 μm |

| Skin Pass | S | Smooth, flat surface | 0.6-0.9 μm |

Tolerance Standards

| Parameter | Tolerance Range |

|---|---|

| Thickness | ±0.01mm - ±0.03mm (depending on thickness) |

| Width | +5mm / -0mm |

| Length | +10mm / -0mm |

| Flatness | ≤6mm/m |

| Camber | ≤2mm/m |

Available Standards

| International Standard | Description |

|---|---|

| EN 10346 / EN 10143 | European Standard |

| ASTM A653 / A653M | American Standard |

| JIS G3302 | Japanese Standard |

| GB/T 2518 | Chinese Standard |

| AS 1397 | Australian Standard |

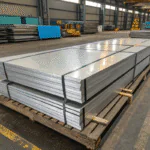

Packaging & Delivery

Standard Export. Packaging.Seaworthy packaging suitable for long-distance transportation

Waterproof Protection.Wrapped with waterproof paper and secured with steel strips

Flexible Options.Wooden pallets available upon request for extra protection

Container Loading. 20-25 MT per 20'GP container for optimal shipping efficiency